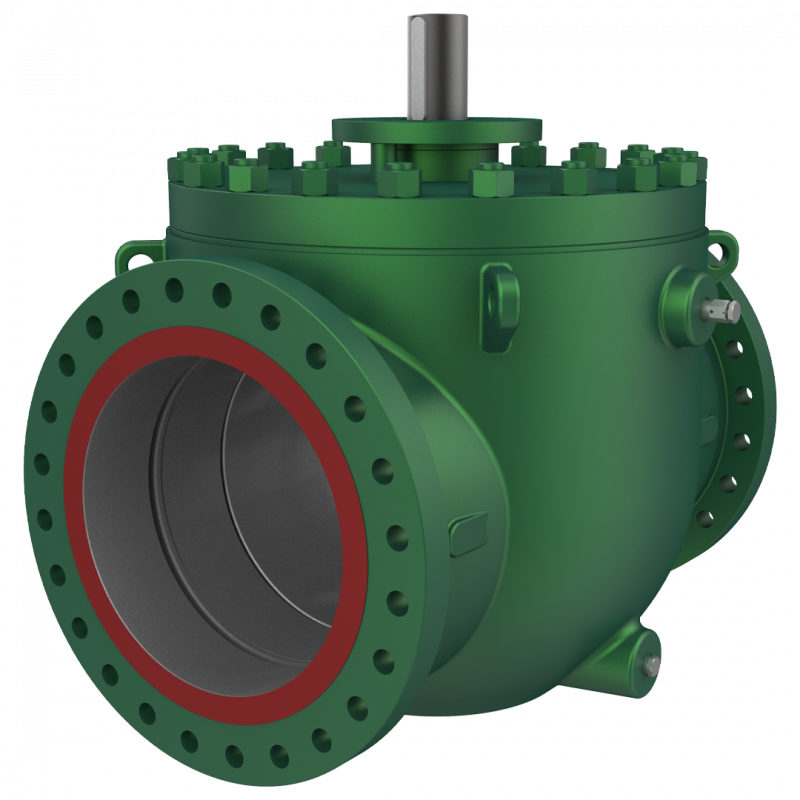

Top-entry trunnion ball valve

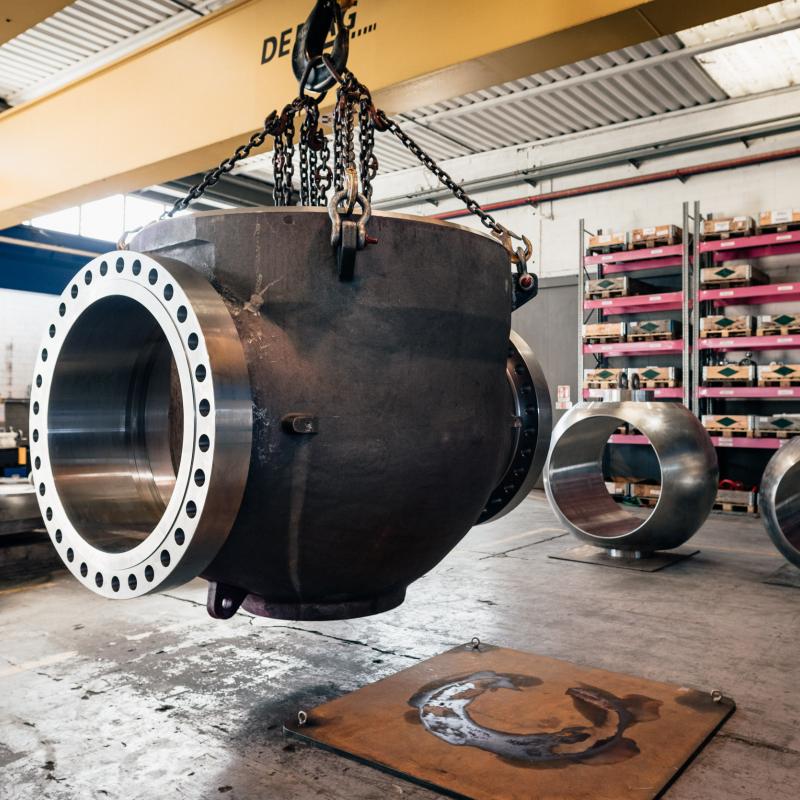

Before assembly

API 6D Top entry ball valves- cast body-

52 inch. ASME 600, Raised face connection, operated by Gear

Before assembly

API 6D Top entry ball valves- cast body-

52 inch. ASME 600, Raised face connection, operated by Gear

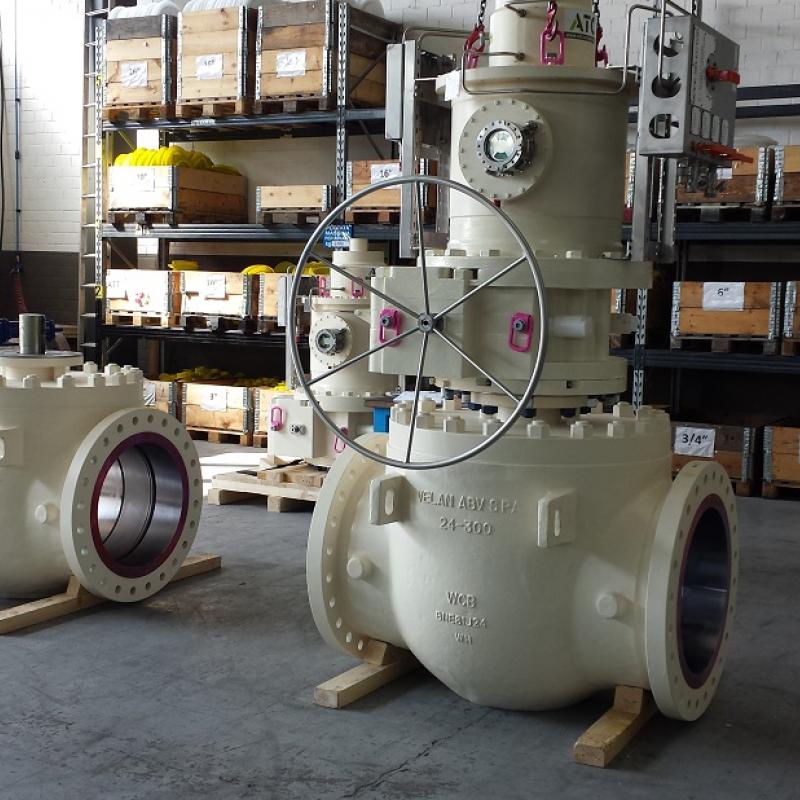

API 6D Top entry ball valve

18 inch. ASME 300, Raised face connections, Operated by Gear box with padlocking

For Pipeline isolation

API 6DSS Subsea Top entry ball valve

24 inch. ASME 300, Raised face connections, Operated by compact hydraulic actuator with mechanical diver

Subsea PLEM Valves. Water depth 30 meters

API 6D Top entry ball valve,

36 inch. ASME 900, Buttwelding connections, Operated by actuator

For Emergency shutdown in pipeline terminal

API 6A Top entry ball valve

7.1/16 Inch. API 10000, 6BX End flange connections, Operated by Gear

Process valves for onshore production plant

API 6D Top entry ball valve

18 inch. ASME 300, Raised face connections, operated by Gear with padlocking

For Pipeline isolation

BTE-BTF-TSB-BTX-TXB

based on API 6D or API 6A or API 6DSS and customer requirements

NPS 2 - 56 (DN 50-1400)

NPS 1.13/16 –16.3/4 (DN 46-425)

RF, RTJ as per B16.5 &B16.47

BW, Butt Welded as per B16.25

Hub connection

6B, 6BX as per API6A

Forged or cast one-piece

Soft or metal seated with hard facing on ball and seats

Self relieving seats

Double piston seats

Double block and bleed design (DBB)

Secondary seals in pure Graphite

Anti-static device

Anti-blowout stem

O-ring/lip seal configuration

Emergency sealant injection on seats and stem available

Low fugitive emission stem packing available

CRA overlay on all dynamic sealing areas or on all wetted parts available

Special maintenance tool for in-line seat disengagement

Stem extension for underground installations available

Manual: wrench or gear with padlocking

Actuated: Pneumatic/ Hydraulic/Electric

Compliance with API 6D & ISO 5208 & API 598 inspection and testing

Compliance with API 6A inspection and testing

Compliance with API 6DSS Inspection and testing

Fire safe and fire tested as per API 6FA/607

SIL 3 Certification as per IEC61508

Fugitive Emission as per ISO15848

PED 2014/68/UE

Available as per API 6A standard:

Product specification levels PSL 1, 2, 3, 3G, and 4

Performance requirement levels PR1, PR2

Design validation as per PR2F

Top-entry trunnion ball valves are the perfect solution for both offshore and onshore systems. Convenience of operation and maintenance are essential features of our design simplifying in-line disassembly for trim inspection or internal repairs even where space is restrictive. Our valves also offer excellent corrosion resistance and superior sealing performance at both high and low pressures. Valves are manufactured in a single forged or cast piece and configured with two independent seats for a bi-directional sealing and are manufactured in accordance with customer specific requirements and international standards.