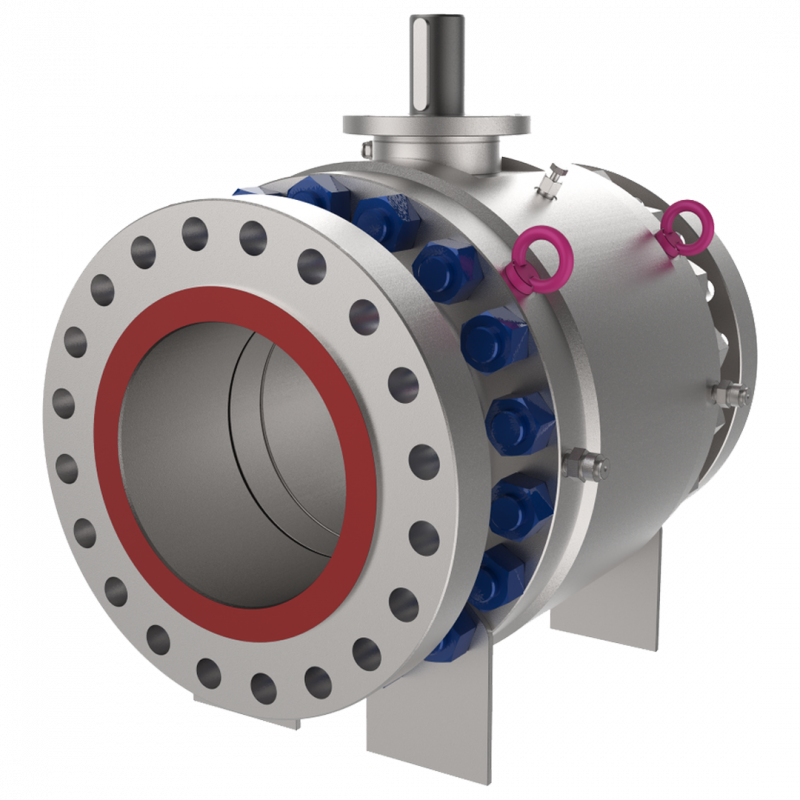

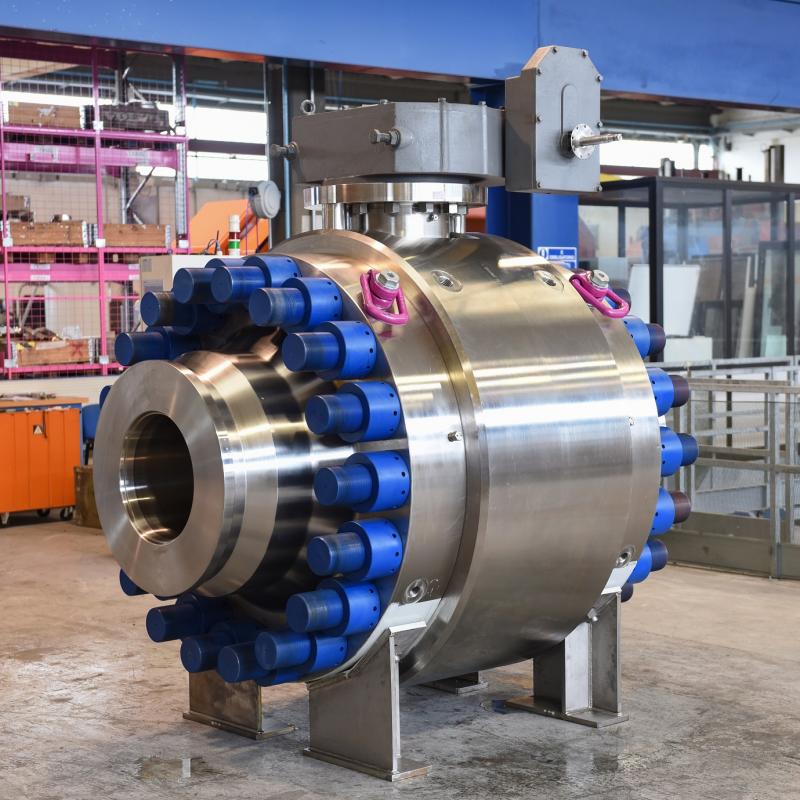

Side-entry trunnion ball valve

API 6D Side entry ball valve 3 piece,

24x20 inch. ASME 2500, Hub connections, operated by Gear

For Isolation process in FPSO topside

API 6D Side-entry ball valve three-piece

20 inch. ASME 900, RTJ connections,operated by Cable Drive actuator

API 6D side entry trunnion ball valve 3 piece

12 inch. ASME 1500, Hub connections, operated by Gear

For Isolation process in FPSO topside

API 6D Side entry ball valve 3 piece

36 & 48 inch. ASME 600, Raised face connections, operated by Gear

Process valves for onshore production plant

API 6D Side entry trunnion ball valve 3 piece

20 inch. ASME 2500, Compact end flange connections NORSOK L-005, operated by Hydraulic actuator,

For Isolation process in FPSO topside

API 6D Side entry ball valve 3 piece

48 inch. ASME 600, Raised face connections, operated by Scotch Yoke Spring Return

For Emergency shutdown in pipeline terminal

API 6D Side entry ball valve 3 piece

30 inch. ASME 600, Raised face connections, operated by Double Acting Pneumatic Actuator

Process valves for onshore production plant

BT2 and BT3

based on API 6D and Customer requirements

NPS 2-56 (DN 50-1400)

RF, RTJ as per B16.5 &B16.47

BW, Butt Welded as per B16.25

SW, Socket Welded as per B16.11

Hub connection

Forged bolted two-piece and three-piece

Soft or metal seated with Hardfacing on ball and seats

Self relieving seats

Double piston seats

Combination seats

Interchangeable seats

Double block and bleed design (DBB)

Secondary seals in pure Graphite

Anti-Static Device

Anti Blow out stem

Emergency sealant injection on seats and stem available

Low fugitive emission stem packing available

O-ring /Lip seals and Graphite configuration

CRA overlay on all dynamic sealing areas or on all wetted parts available

Extended bonnet for low & high temperature available

Manual: wrench or Gear with padlocking

Actuated: Pneumatic/ Hydraulic/Electric

Compliance with API 6D & ISO 5208 & API 598 inspection and testing

Fire safe and fire tested as per API 6FA/ 607

SIL 3 Certification as per IEC61508

Fugitive Emission as per ISO15848

PED 2014/68/UE

Side-entry ball valves are manufactured in accordance with API 6D standards. The complete range of forged valves is designed in two or three bolted pieces with a solid double trunnion configuration and two independent seats for an easy bidirectional sealing, to ensure the greatest level of tightness and reliability under high pressure and temperature conditions in all critical isolation services.

Materials selection is fully customizable to meet the customer's project specifications and several unique features are available to offer an enhanced technical solution suitable to aggressive offshore environments and corrosive and abrasive fluids.