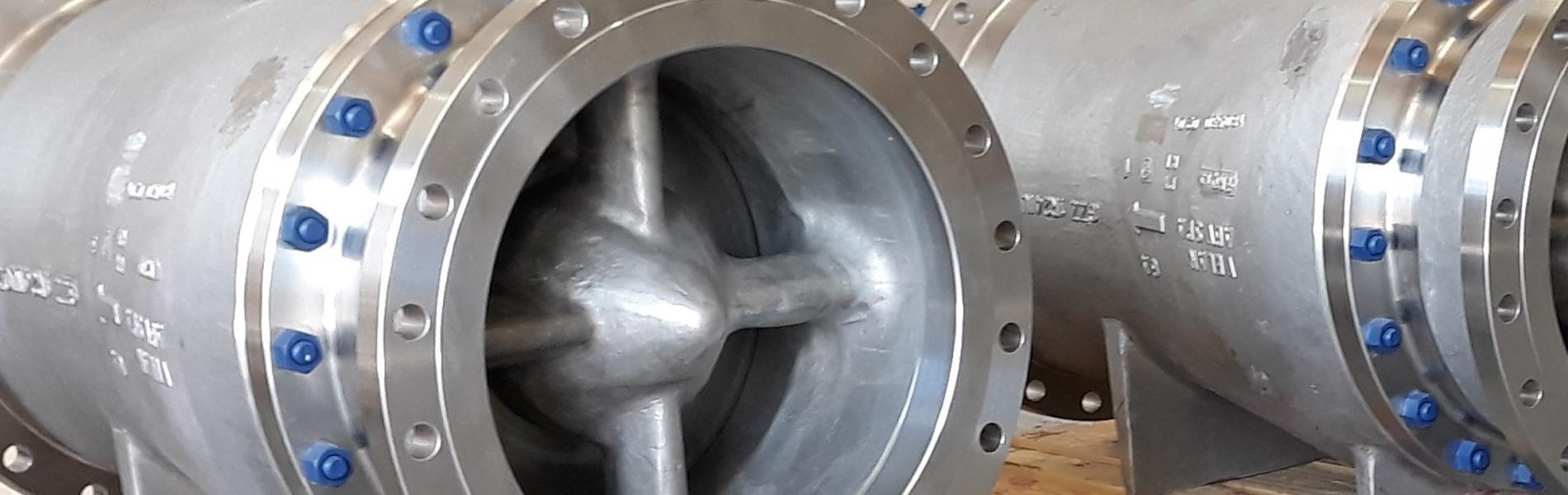

Dual plate check valve

Proquip dual plate check valve-Lug configuration

12 inch. ASME 2500,Ring joint connections, automatic operated

in FPSO Facilities

Proquip Dual plate check valve-Lug configuration

20 inch. ASME 150, Raised face connections, automatic operated

In FPSO Facilities

DPW

DPF

DPH

DPM

based on API 594 standard and customer requirements

NPS 2-48 (DN 50- 1200)

RF, RTJ as per B16.5 &B16.47

Lug, Wafer or Double flanged configuration in forged or cast one-piece

Metal-seated with hardfacing on disks and seat

Retainerless design-no holes through the body wall, therefore emission-free

Light-weight discs for fast closing without backflow

Shock bumpers- extended cycle life of valve trim with minimal wear under the most severe services

Spring assisted design

Extended seat life- no dragging effect in the valve fully open position. The integrity of the sealing area is extended

Good dynamic response

Low pressure drop

Intrinsically fire safe- no drilling through the body wall

Compact and lightweight

automatic

Compliance with API 594 or API 6D,ISO 5208 and API 598 inspection and testing

Fire safe and fire tested as per API 6FA/607

PED 2014/68/UE

Proquip dual-plate check valves offer a unique compact design with high performance. The special retainerless body and the quick acting spring provide a fast-acting response to flow reversal, minimizing stress and maximizing service life.

The valve is designed with two discs hinged at their sides like a door, eliminating the effect of gravity. Consequently, very little energy is needed to open the valve and maintain this position, resulting lower energy loss.

The reduced weight of a dual-plate valve disc versus the full-bodied swing check is a major factor in minimizing slamming and water hammer–making it the optimal solution to ensure system safety. Material selection is fully customizable to meet customers project specifications